Product Engineering

Organisation of introducing and improving the products

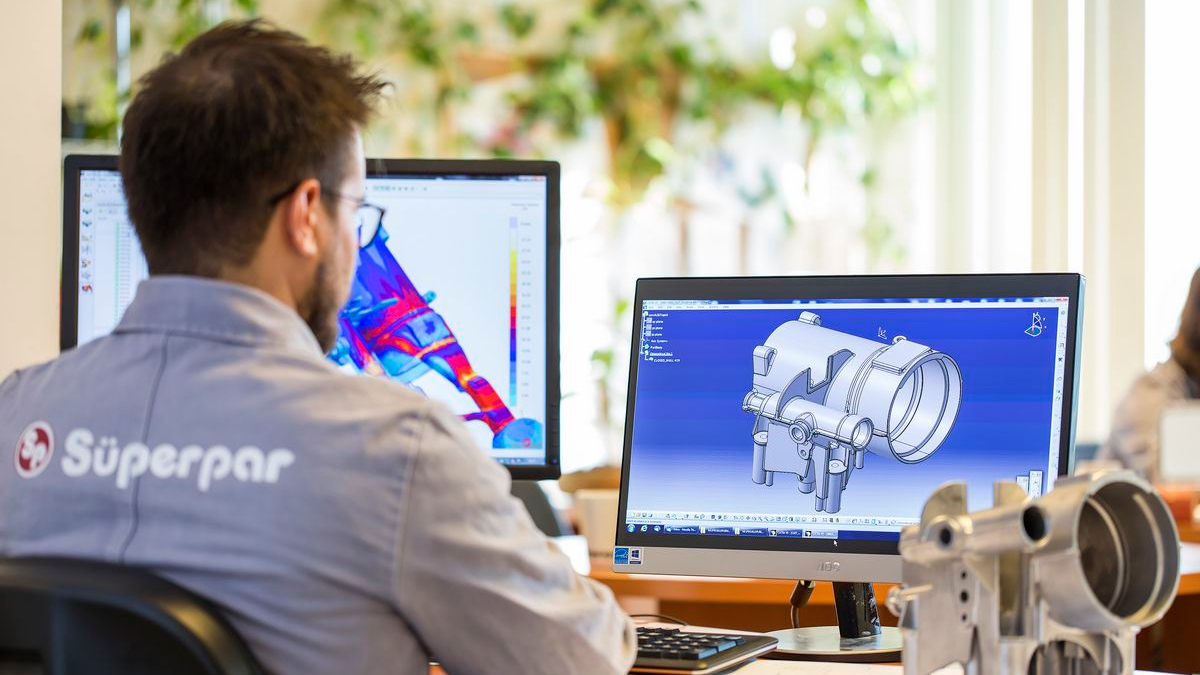

Product Enginnering assist SUPERPAR customers in every step of the project from design to mass production. Tool production begins with part design. Most appropriate solution is offered to our customer's requirements with merging MAGMA simulation program and casting experience. If requested, part desing is analysed in view of endurance with ANSYS program. Part desing is improved under major titles of endurance, casting, tooling, measuring and machining. With prototype tool production analysis results can be reviewed and physical tests can be done before mass production.

In tool production SUPERPAR serves her customer with Catia, Siemens NX, Autocad Invertor, Magma Simulation, Powermill CAM programs. To keep the quality in best level DMG_HSC_75 5 exen CNC machine etc are used. Tool production process is finished with pilot castings and validation process. Besides casting tools SUPERPAR offers full solutions to her customers with desing and production of trimming tools, machining, assembly, test apparatus.